TMS, WMS, and OMS: Which Is Better?

Systems that manage the flow of your goods are advancing. Information technology in the supply chain can work wonders for your business. However, choosing the right system is essential. Management systems can improve productivity and streamline processes. Some systems are more suitable for internal functions. Others are better for external use.

Although many systems are available, some will better suit your needs than others. Gaining network visibility and crucial data can empower your business. You must understand your business needs to make the right software choice. Learn the meaning of OMS, TMS, and WMS and how these systems are different.

What Is the Difference Between TMS and OMS?

TMS stands for transport management system. A TMS is software that can manage transport in your supply chain. This system allows you to govern and manage your fleet. You can schedule drivers and plan rounds with this system. You can also organize loading and unloading processes and invoices with this system.

These systems are transport management's operational, tactical, and strategic side. You can use them to analyze your activity in real time. This feature empowers you to adapt to customer demands and propose efficient solutions.

A TMS is ideal for carriers and shippers. For shippers, the system can help generate calls from suppliers to optimize costs. The system can plan rounds for carriers to optimize resources and reduce downtime.

An order management system (OMS) can oversee inventory management and ensure operations run steadily. This system is often for the front end of the business. The OMS can accept orders and route them to the correct facility. Although the OMS can act as a stand-in for a warehouse management system (WMS), it can lack some functions. For example, the OMS may not provide some labor management that a WMS offers.

What Can WMS Do for Businesses?

WMS stands for warehouse management system. This computer program helps optimize stock management within a warehouse facility. The system shows you the state of your stocks and helps optimize fulfillment services. You can coordinate, optimize, and control flows to and from your facility. You can also use a WMS to trace your products throughout the warehouse.

Using complex logistics software with a WMS helps you get the most from these systems. This pair enables you to supervise product flow and gather information throughout the facility. Tracking reception and shipment allows you to allocate management and material resources better. This way, you can fulfill orders promptly.

A WMS has forecasting abilities that can predict peaks in activity. These algorithms empower logistics managers to assign the proper teams to the correct locations to avoid downtime. Traceability tools ensure you can store materials and prepare orders accurately and quickly.

The largest benefits of the WMS are storage optimization and storage cost reduction. You can also use the system to analyze consumption and increase service rates. Resizing your stock can help you reduce fixed assets and preparation errors.

The difference between TMS and WMS is their internal or external use. The TMS is suitable for managing transportation activities. The WMS offers internal management. These tools often complement each other and share a common objective. Ultimately, they both empower companies to reach success through reporting to analyze your strengths and weaknesses.

What Makes TMS Different: Choosing the Right System

Choosing the right system is vital. The right management system can boost productivity and reduce costs and downtime. You must assess your needs to understand which system is most beneficial for your business.

For example, vendors selling in multiple locations may benefit from an OMS. Shippers wanting to reduce shipping time and cost can use TMS. Warehouses needing to manage inventory may use a WMS.

All three systems have unique capabilities. You can use them together for a seamless experience. A TMS is often an ideal choice if you're looking for only one system. TMS systems can handle functions throughout the life cycle of a load. For instance, you can optimize routes, select modes, and manage carriers, performance, and contracts.

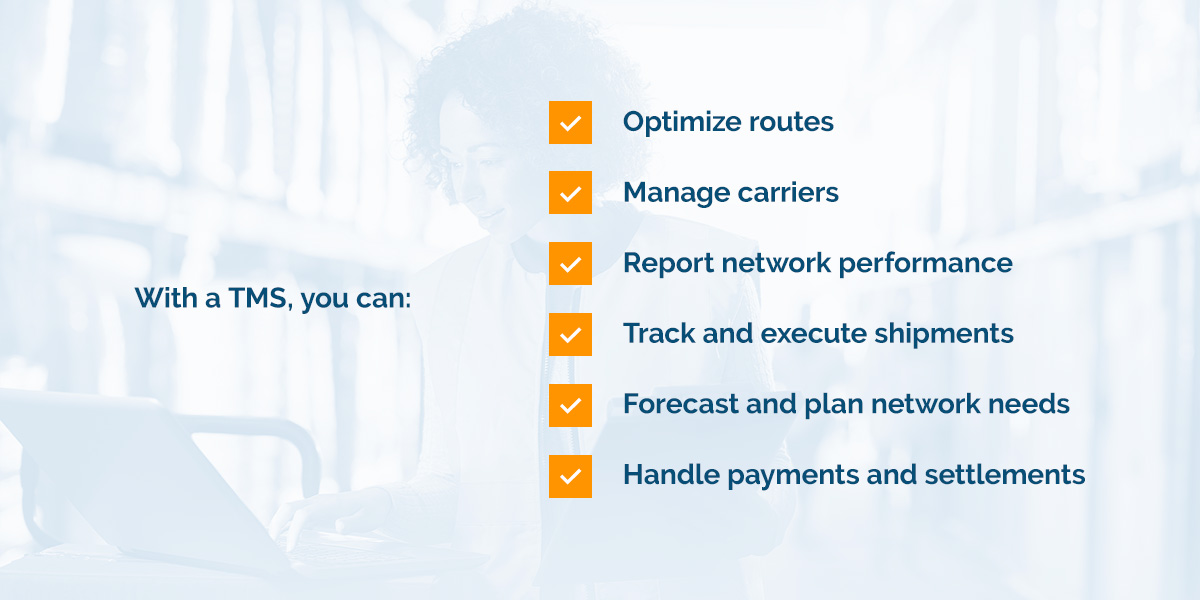

This system provides a complete view of network performance and day-to-day supply chain visibility. With a TMS, you can:

- Optimize routes

- Manage carriers

- Report network performance

- Track and execute shipments

- Forecast and plan network needs

- Handle payments and settlements

These functions provide status updates about freight, booking and tendering loads, auditing, billing, and settling for payments. TMS systems allow you to find rates to optimize each shipment and save time on the front end. This process saves money and time throughout the shipping process.

TMS tracking gathers and consolidates records of shipment movements, tracking loads from the warehouse to the final destination. You can receive real-time updates and measure carrier performance.

Payment functions allow you to audit each invoice and pay carriers easily. You can access cost analytics to understand your expenses and profits better. Additionally, you can find in-depth reporting for other areas to plan future actions. This process empowers you to continuously improve and reduce unnecessary expenses.

Benefits of Choosing a TMS

As you can see, a TMS offers many unique functions. This system is excellent for various companies looking to save time and money. Benefits of a TMS system include:

- Automating day-to-day tasks.

- Forecasting needs and strategies.

- Managing carriers, routes, and rates.

- Optimizing delivery means and processes.

- Improving traceability of deliveries and products.

- Accessing reports to cut expenses and monitor productivity.

- Clarifying and standardizing information for clear communication with drivers.

- Creating a better vision of activity to identify pain points and address them quickly.

- Allowing better management for export constraints, multimodal transport, and delivery priorities.

Streamline Operations With ShipERP

ShipERP fosters digital supply chain transformation. From global enterprises to privately held businesses, we proudly serve a range of companies. We help our clients automate and increase efficiencies across processes. We rely on real-time information and enterprise systems to help businesses reduce costs and increase profits.

We're a recognized leader in the industry. ShipERP proudly focuses on SAP and research and development. We build strong partnerships and have a proven track record. When you need a management system, trust ShipERP.

Our SAP Transportation Management can streamline shipping operations. Our tools and expertise can get the job done cost-effectively and efficiently. Direct integration lets you easily handle tracking, label generation, and carrier rate quoting.

ShipTM is your comprehensive solution. With us, you can empower your processes by:

- Streamlining shipping processes

- Accessing global carrier coverage

- Directing POD attachments to orders

- Sending electronic invoices through various carriers

- Standardizing event statuses for tracking and communication

For more information about how we can help your business, reach out to our team.